Grooved couplings and fittings are an essential part of many industrial applications, offering a reliable and efficient way to connect pipes and tubes. While both grooved and threaded fittings serve the same purpose, they have some key differences that set them apart. In this article, we will explore the main differences between grooved and threaded fittings, and why grooved fittings are becoming increasingly popular.

Grooved Couplings and Fittings

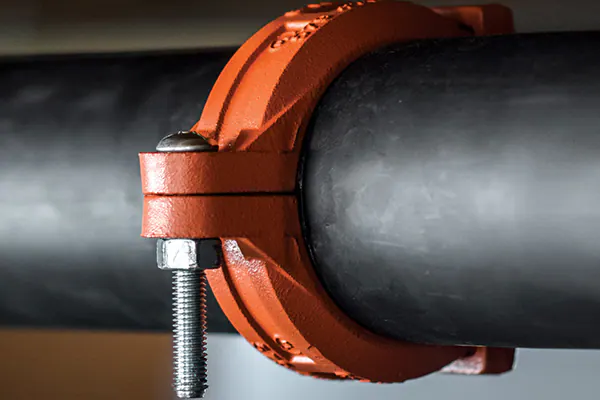

Grooved couplings and fittings are designed to connect pipes and tubes flexibly, allowing for movement and vibration. They are typically made of a durable material, such as stainless steel or carbon steel, and have a grooved design that allows for easy installation and removal. The grooves on the fitting are designed to grip the pipe or tube, creating a secure connection that can withstand high pressures and temperatures.

Threaded Fittings

Threaded fittings, on the other hand, are designed to connect pipes and tubes more permanently. They have a threaded design that screws into the pipe or tube, creating a secure connection that is resistant to movement and vibration. Threaded fittings are typically made of the same materials as grooved fittings, such as stainless steel or carbon steel, and are commonly used in applications where a permanent connection is required.

Key Differences

The main difference between grooved and threaded fittings is their design and installation method. Grooved fittings have a grooved design that allows for easy installation and removal, while threaded fittings have a threaded design that screws into the pipe or tube. Additionally, grooved fittings are typically used in applications where flexibility is required, while threaded fittings are used in applications where a permanent connection is required.

Advantages of Grooved Fittings

Grooved fittings have several advantages over threaded fittings. They are easier to install and remove, reducing the time and effort required for maintenance and repairs. They also offer greater flexibility, allowing for movement and vibration without compromising the connection. Grooved fittings are also less prone to leaks and are more resistant to high pressures and temperatures.

Disadvantages of Threaded Fittings

Threaded fittings, on the other hand, have some disadvantages compared to grooved fittings. They are more difficult to install and remove, requiring specialized tools and expertise. They are also less flexible, which can lead to leaks and other issues in applications where movement and vibration are present.

Conclusion

In conclusion, grooved couplings and fittings are an excellent choice for industrial applications where flexibility and ease of installation are important. While threaded fittings have their advantages, grooved fittings offer a more reliable and efficient connection that can withstand high pressures and temperatures. With their ease of installation and removal, grooved fittings are becoming increasingly popular in a wide range of industries.

Comments