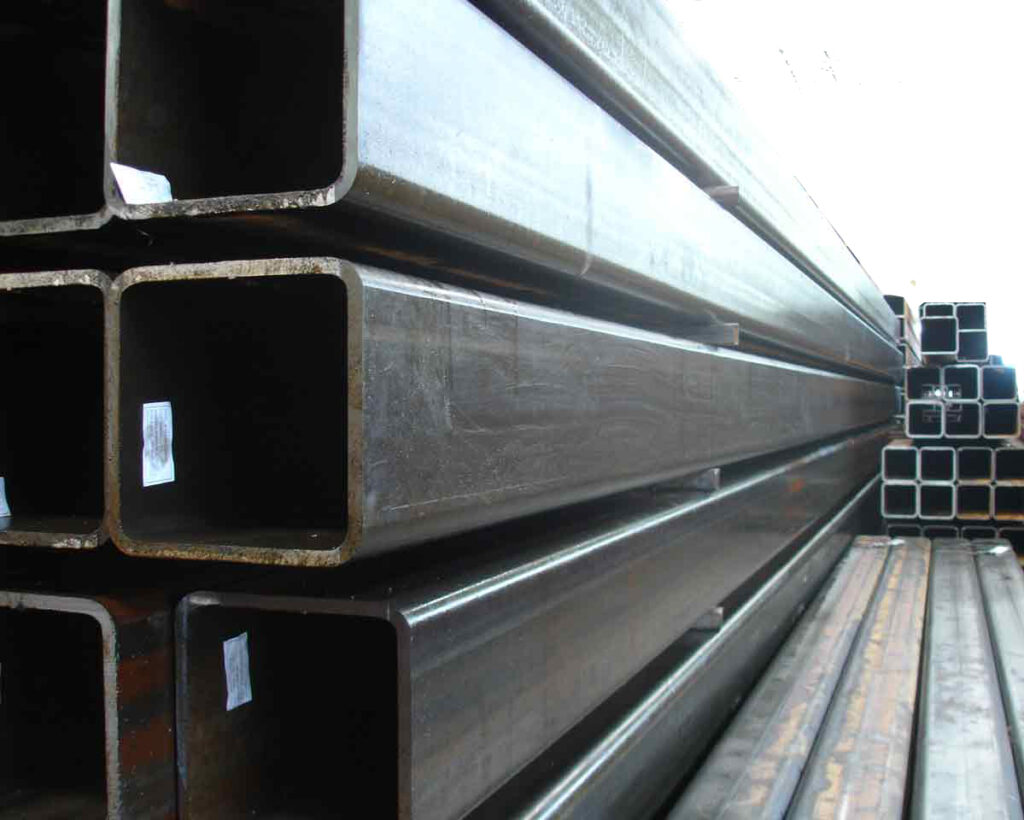

This article provides a detailed overview of the production process for 1/2 Steel Square Bar. The process involves several steps, including melting, casting, rolling, and finishing. Each step is critical in ensuring the quality and consistency of the final product. This article also covers the properties and applications of 1/2 Steel Square Bar, making it a valuable resource for anyone interested in this type of steel.

Introduction

Steel square bars are essential in various industries, from construction to manufacturing. One of the most commonly used sizes is the 1/2 Steel Square Bar. This article will provide a comprehensive guide on the production process of 1/2 Steel Square Bar, from melting to finishing.

Melting and Casting

The first step in producing 1/2 Steel Square Bar is melting. Steel scrap and other raw materials are melted in a furnace at extremely high temperatures. Once the steel is in a liquid state, it is poured into a mold to create billets. The billets are then left to cool and solidify.

Rolling

After the billets have solidified, they are reheated and passed through a series of rollers to reduce their size and shape. The rolling process involves several stages, with each pass reducing the size of the billet until it reaches the desired dimensions. The final pass is done at room temperature to ensure the steel’s strength and durability.

Finishing

Once the steel has been rolled to the desired size and shape, it undergoes a finishing process. This involves straightening the steel and cutting it to the required length. The steel is then inspected for any surface defects or imperfections. If any issues are found, the steel is sent back for reworking.

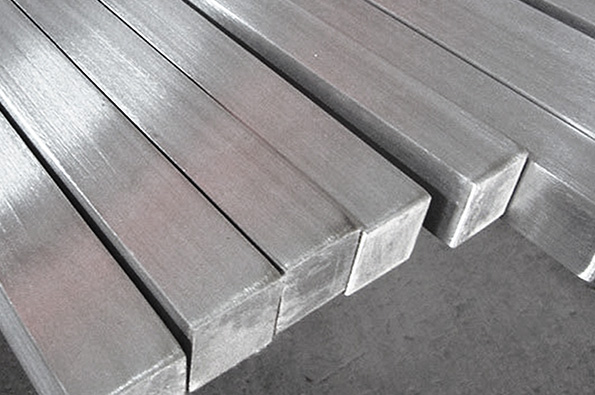

Properties and Applications

1/2 Steel Square Bar has excellent mechanical properties, making it suitable for a wide range of applications. It has high tensile strength, good ductility, and excellent corrosion resistance. The square shape of the bar makes it easy to weld and provides excellent load-bearing capabilities, making it ideal for use in construction, manufacturing, and engineering.

Conclusion

In conclusion, producing 1/2 Steel Square Bar involves several critical steps, including melting, casting, rolling, and finishing. Each step plays a crucial role in ensuring the quality and consistency of the final product. 1/2 Steel Square Bar is a versatile and durable steel that finds use in various industries, making it an essential material for modern society.

Comments