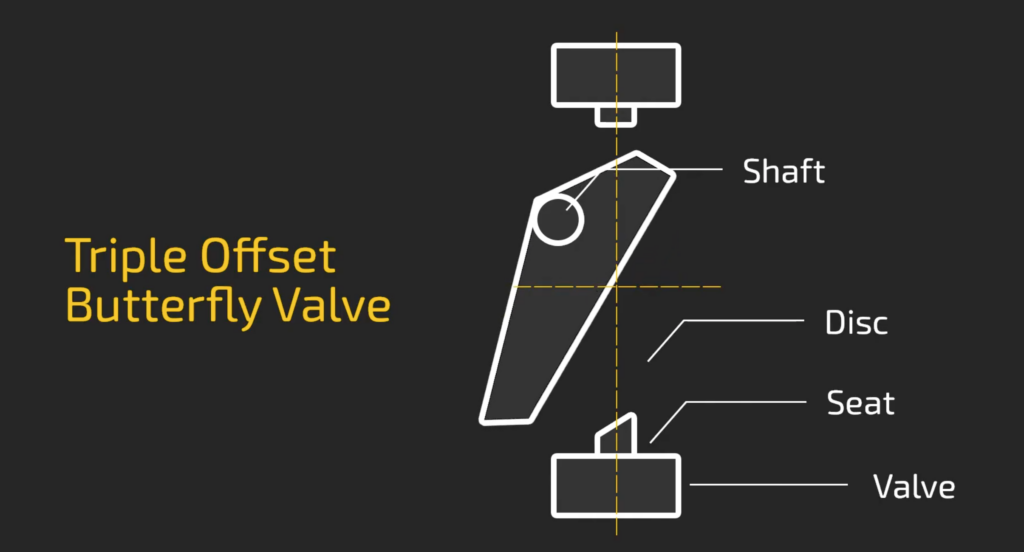

This article explores the benefits of using a triple offset butterfly valve, including its leak-tight seal, reduced maintenance, and longer service life. It also compares the design of triple offset butterfly valves to other offset valves and provides a drawing of the valve’s construction.

Introduction:

Triple offset butterfly valves are designed to provide reliable, leak-tight performance in a variety of industrial applications. These valves are known for their unique design, which features three offsets in the disc and seat geometry to provide a bubble-tight seal. This article will discuss the benefits of using a triple offset butterfly valve, compare it to other offset valves, and provide a drawing of the valve’s construction.

Benefits of Triple Offset Butterfly Valves:

Triple offset butterfly valves offer several advantages over other valve types. One of the most significant benefits is their leak-tight seal, which is achieved through the valve’s three offsets in the disc and seat geometry. This design provides a bubble-tight seal that is ideal for applications that require precise control of flow or isolation of hazardous materials.

Another benefit of triple offset butterfly valves is reduced maintenance. The valve’s unique design allows for minimal wear and tear on the sealing surfaces, resulting in longer service life and reduced downtime. Additionally, the valve’s metal-to-metal sealing provides increased resistance to wear and corrosion, further reducing maintenance requirements.

Triple offset butterfly valves are also known for their high-temperature capabilities. The valve’s metal-to-metal sealing can withstand extreme temperatures, making it ideal for use in high-temperature applications. This feature also makes the valve suitable for use in cryogenic applications, as it can maintain its bubble-tight seal even at extremely low temperatures.

Comparison to Other Offset Valves:

Triple offset butterfly valves differ from other offset valves in several ways. Double offset butterfly valves, for example, only feature two offsets in the disc and seat geometry, resulting in a less precise seal. Additionally, double offset butterfly valves are more prone to wear and require more frequent maintenance.

Triple offset butterfly valves also differ from triple offset metal-seated valves, which feature an all-metal construction. While both valves provide a bubble-tight seal, triple offset butterfly valves offer several advantages over their metal-seated counterparts. For example, triple offset butterfly valves are lighter in weight, require less maintenance, and are more cost-effective.

Applications Of Triple Offset Butterfly Valve

Triple offset butterfly valves are versatile and can be used in a wide range of industrial applications. Some of the most common applications include:

- Oil and gas production: Triple offset butterfly valves are ideal for use in the oil and gas industry due to their ability to withstand high pressures and temperatures. They are often used for applications such as pipeline isolation, tank farms, and offshore drilling platforms.

- Chemical processing: The precise control of flow provided by triple offset butterfly valves makes them an ideal choice for chemical processing applications, such as metering and regulating the flow of chemicals.

- Power generation: Triple offset butterfly valves are commonly used in power plants for applications such as steam isolation, turbine bypass, and cooling water control.

- Water and wastewater treatment: The leak-tight seal provided by triple offset butterfly valves makes them ideal for use in water and wastewater treatment applications, such as pump isolation and flow control.

- Food and beverage production: Triple offset butterfly valves are often used in the food and beverage industry due to their ability to provide a sanitary, non-contaminating seal. They are commonly used for applications such as product isolation and flow control.

Conclusion:

Triple offset butterfly valves offer a range of benefits over other valve types, including their leak-tight seal, reduced maintenance, and high-temperature capabilities. While other offset valves may provide similar functionality, triple offset butterfly valves offer superior precision and durability, making them an ideal choice for a variety of industrial applications.

Comments