A stainless steel butterfly valve is a type of valve used for regulating the flow of liquids and gases in industrial processes. It consists of a disc that rotates around a central axis to control the flow of fluid. In this article, we will explore the working principle of a stainless steel butterfly valve, including its components, types, and applications. By understanding the principles behind the stainless steel butterfly valve, industrial professionals can choose the right equipment for their specific applications and maximize efficiency in their processes.

Introduction

A stainless steel butterfly valve is a type of valve used in industrial processes for regulating the flow of liquids and gases. It consists of a disc that rotates around a central axis to control the flow of fluid. In this article, we will explore the working principle of a stainless steel butterfly valve, including its components, types, and applications.

Components of a Stainless Steel Butterfly Valve

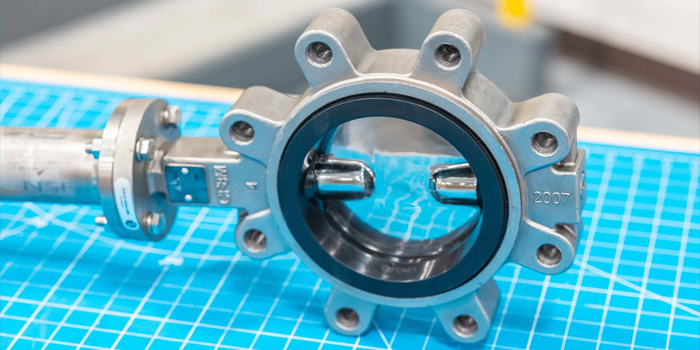

A typical stainless steel butterfly valve consists of four main components: the body, the disc, the stem, and the actuator. The body is the outer shell that contains the valve and connects it to the piping system. The disc is the part of the valve that rotates to control the flow of fluid. The stem connects the disc to the actuator, which is the device used to control the valve’s position.

Working Principle of a Stainless Steel Butterfly Valve

The working principle of a stainless steel butterfly valve involves opening and closing the valve by rotating the disc around a central axis. When the disc is perpendicular to the flow of fluid, the valve is closed, and when it is parallel to the flow, the valve is open. The actuator controls the valve’s position by rotating the stem, which in turn rotates the disc.

Types of Stainless Steel Butterfly Valves

Stainless steel butterfly valves come in different types to suit different applications. The most common types are wafer-style, lug-style, and flanged valves. Wafer-style valves are designed for use between two flanges and are easy to install and remove. Lug-style valves have threaded inserts on both sides of the valve body, allowing them to be installed without using flanges. Flanged valves are designed for use with flanges and provide a more secure connection.

Applications of Stainless Steel Butterfly Valves

Stainless steel butterfly valves are used in a wide range of industrial applications, including water treatment, food and beverage production, and chemical processing. For example, in the water treatment industry, stainless steel butterfly valves are used to regulate the flow of water in pipelines and control the level of water in storage tanks. In the food and beverage industry, they are used to control the flow of ingredients and finished products during production.

Conclusion

A stainless steel butterfly valve is a versatile and efficient piece of equipment used in a wide range of industrial applications. By understanding the different types of valves and their working principles, industrial professionals can choose the right equipment for their specific applications and maximize efficiency in their processes. Whether you’re in the water treatment, food, and beverage, or chemical processing industry, a stainless steel butterfly valve can help you achieve optimal results in your fluid control processes.

Comments