Explore the various types of butterfly valves and their applications in different industries. Learn about the benefits and considerations for each type, including wafer, lug, double-offset, and triple-offset butterfly valves. Discover how these valves provide reliable flow control in water treatment, HVAC, oil and gas, and other applications. Read now to gain insights into the different types of butterfly valves and make informed decisions for your projects.

Introduction:

Types of Butterfly Valve: A Key Element in Flow Control

Understanding the different types of butterfly valves is crucial for professionals involved in flow control applications. These valves offer a versatile and efficient solution for regulating fluid flow in various industries. In this comprehensive guide, we will explore the types of butterfly valves, highlighting their features, applications, and considerations for selection.

Summary:

Discover the World of Butterfly Valves: Types and Applications

Explore the wide range of butterfly valves and their significance in flow control applications. From wafers and lugs to double-offset and triple-offset butterfly valves, each type has unique features and benefits. Understanding the applications and considerations for selection will help you make informed decisions. Read on to gain insights into the different types of butterfly valves and their role in water treatment, HVAC, oil and gas, and more.

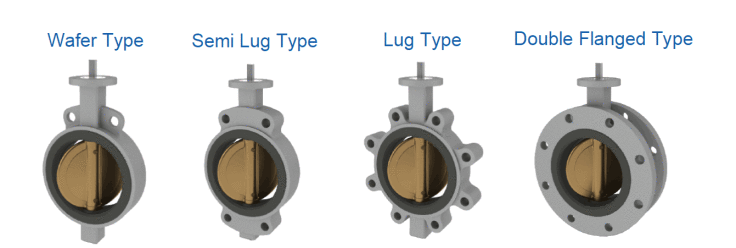

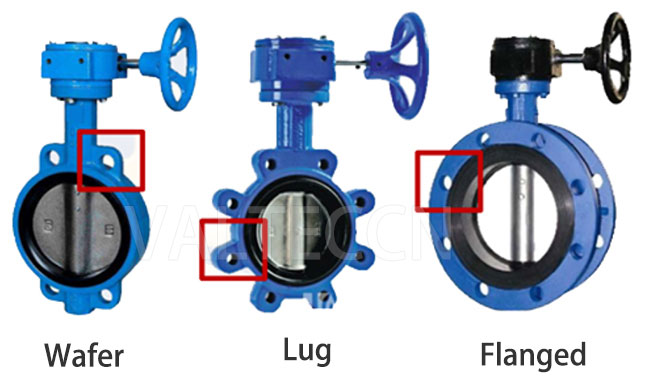

Wafer Butterfly Valve:

Compact Design for General Applications

The wafer butterfly valve is a popular choice for general-purpose applications. Key features include:

- Compact Design: Wafer butterfly valves have a slim profile, making them lightweight and easy to install between flanges.

- Cost-Effective: These valves offer a cost-effective solution for applications with moderate pressure and temperature requirements.

- Suitable for Low-Pressure Systems: Wafer butterfly valves are commonly used in HVAC, water treatment, and low-pressure industrial systems.

Lug Butterfly Valve:

Versatile and Easy to Maintain

Lug butterfly valves provide versatility and ease of maintenance. Key features include:

- Bi-Directional Sealing: Lug butterfly valves can seal in both directions, allowing installation and maintenance without disrupting the flow.

- Added Stability: The lugs on the valve body provide stability during installation and enable easy removal of the valve from the pipeline.

- Suitable for High-Pressure Applications: Lug butterfly valves are commonly used in applications requiring higher pressure ratings, such as oil and gas pipelines.

Double-Offset Butterfly Valve:

Enhanced Performance and Sealing

The double-offset butterfly valve offers improved performance and sealing capabilities. Key features include:

- Reduced Friction and Wear: The double-offset design minimizes friction between the disc and the seat, enhancing valve life and reducing maintenance.

- High-Temperature Resistance: These valves can withstand higher temperatures, making them suitable for applications in power generation and chemical industries.

- Excellent Bubble-Tight Shut-Off: Double-offset butterfly valves provide reliable sealing, minimizing leakage and ensuring efficient flow control.

Triple-Offset Butterfly Valve:

Superior Performance in Critical Applications

The triple-offset butterfly valve offers superior performance and tight shut-off in critical applications. Key features include:

- Metal-to-Metal Sealing: The triple-offset design provides a metal-to-metal sealing mechanism, ensuring bubble-tight shut-off even in high-pressure and high-temperature environments.

- Excellent Corrosion Resistance: These valves are often used in industries where corrosion resistance is crucial, such as oil and gas, chemical, and petrochemical industries.

- Ideal for Severe Service Conditions: Triple-offset butterfly valves excel in applications requiring resistance to abrasive media, high pressures, and extreme temperatures.

Conclusion:

Selecting the Right Butterfly Valve for Optimal Flow Control

Understanding the different types of butterfly valves and their applications is essential for effective flow control in various industries. Whether it’s the compact design of wafer butterfly valves, the versatility of lug butterfly valves, the enhanced performance of double-offset butterfly valves, or the superior sealing capabilities of triple-offset butterfly valves, each type offers specific advantages. By considering the requirements of your application, you can select the most suitable butterfly valve to ensure reliable flow control and optimize your project’s success.

Comments