Are you in search of a reliable and durable piping solution for your next project? Look no further than split flanged pipes! In this article, we will explore the various uses and benefits of split flanged pipes, and why they are an excellent choice for a wide range of applications.

Introduction

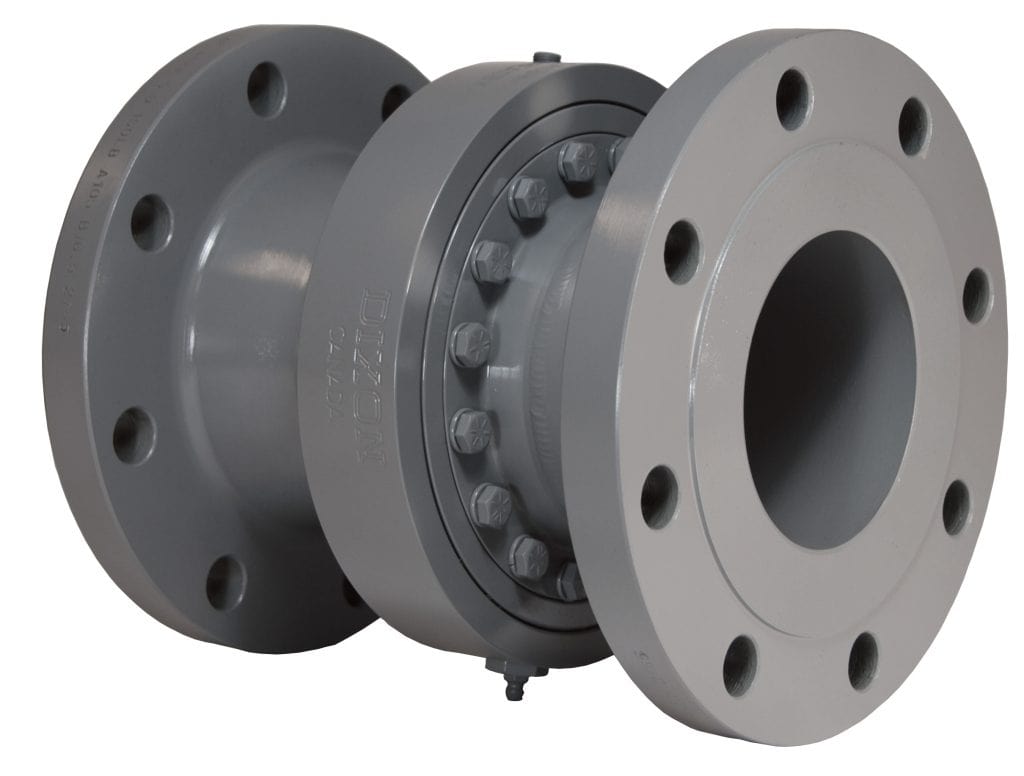

Split flanged pipes are a type of pipe that is designed to be easily installed and removed. They consist of a split pipe and a flange that is welded to the pipe ends. The flange provides a flat surface for the pipe to sit on, allowing it to be easily connected and disconnected. This design makes split flanged pipes ideal for applications where pipes need to be frequently inspected, cleaned, or replaced.

Industrial Applications

Split flanged pipes are commonly used in industrial settings, such as factories, power plants, and refineries. They are often used to transport fluids, gases, and slurries in applications where high pressure and temperature resistance are required. The split design allows for easy maintenance and repair, reducing downtime and increasing productivity.

Municipal Applications

Split flanged pipes are also widely used in municipal applications, such as water treatment plants, sewage systems, and storm drains. They are ideal for transporting water, wastewater, and stormwater, as they can withstand the high pressures and corrosive environments found in these systems. The flanged ends make it easy to connect and disconnect pipes, allowing for quick and easy maintenance.

Agricultural Applications

Split flanged pipes are also used in agricultural applications, such as irrigation systems and livestock watering systems. They are ideal for transporting water over long distances and in harsh environments. The split design allows for easy repair and maintenance, reducing downtime and increasing crop yields.

Benefits of Split Flanged Pipes

There are several benefits to using split flanged pipes, including:

- Easy installation and maintenance: The split design allows for easy installation and maintenance, reducing downtime and increasing productivity.

- Durability: Split flanged pipes are made from high-quality materials that can withstand high pressures, temperatures, and corrosive environments.

- Versatility: Split flanged pipes can be used in a wide range of applications, including industrial, municipal, and agricultural settings.

- Cost-effective: Split flanged pipes are a cost-effective solution for piping needs, as they can be easily reused and repurposed.

Choosing the Right Split Flanged Pipe

When choosing a split flanged pipe, there are several factors to consider, including:

- Material: Split flanged pipes are made from a variety of materials, including stainless steel, carbon steel, and PVC. Choose a material that is appropriate for your application and environment.

- Size: Split flanged pipes come in a range of sizes, from small to large. Choose a size that is appropriate for your application and flow rate.

- Pressure rating: Split flanged pipes have different pressure ratings, ranging from low to high pressure. Choose a pipe with a pressure rating that meets your application requirements.

- Flange style: Split flanged pipes come with different flange styles, including weld neck, slip-on, and blind flanges. Choose a flange style that is appropriate for your application and connection needs.

Conclusion

Split flanged pipes are a versatile and reliable solution for a wide range of piping needs. Their ease of installation, durability, and cost-effectiveness make them an excellent choice for industrial, municipal, and agricultural applications. By considering the factors outlined above, you can choose the right split flanged pipe for your next project, ensuring success and efficiency.

Comments